I personally think it is a stripped down version of the Apo Rodagon D 75mm in 1x version!

1x version: http://www.macrolenses.de/ml_detail.php?ObjektiveNr=154

2x version: http://www.macrolenses.de/ml_detail.php?ObjektiveNr=253

I also have a f4 version of the same lens, so it seems to be common that Rodenstock made special, industrial versions of that one.

http://www.macrolenses.de/ml_detail.php?ObjektiveNr=123

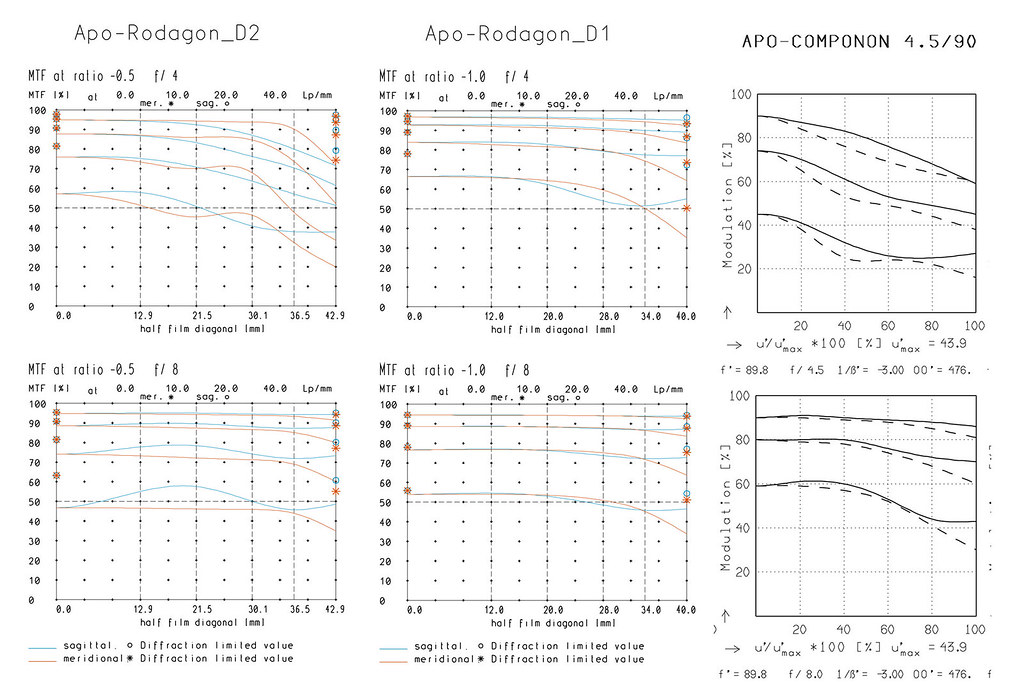

MTF in comparison:

Full lens + MTF (also f5.5) data is here (n german): http://www.rodenstock-photo.com/medi...3-62__8225.pdf

.

Reply With Quote

Reply With Quote

)

)

Bookmarks