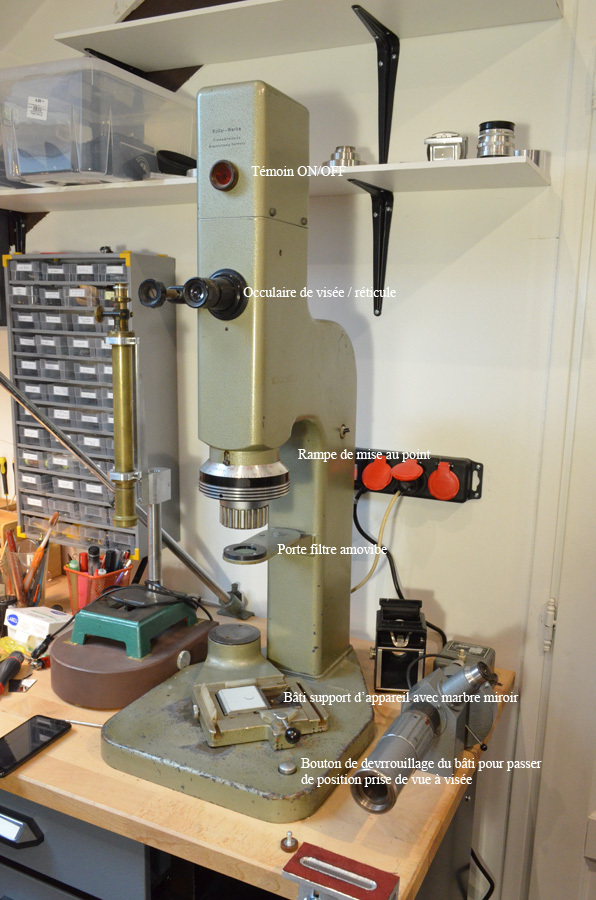

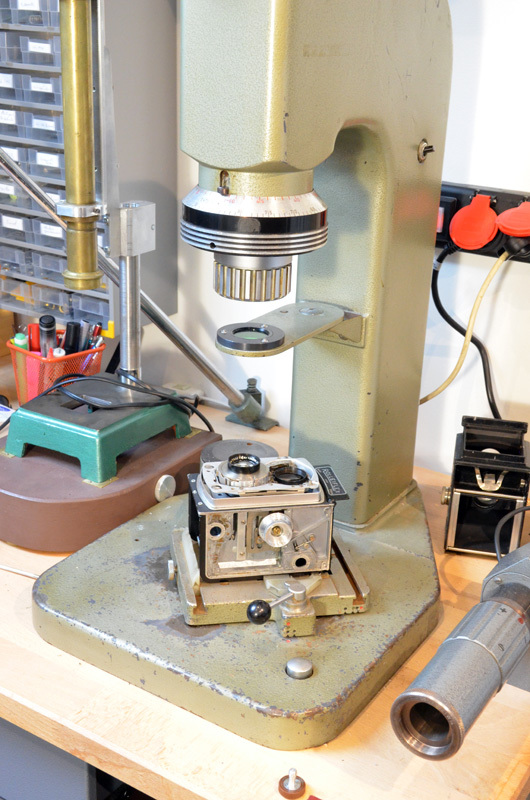

Hello. I am proud to announce the workshop opened today, and has already cameras to repair.

If you look for some nice cameras, you can have a look at some that are available for sale here :

https://www.optomeca.fr/achat-vente/

Thanks for your interest !

Reply With Quote

Reply With Quote

Bookmarks