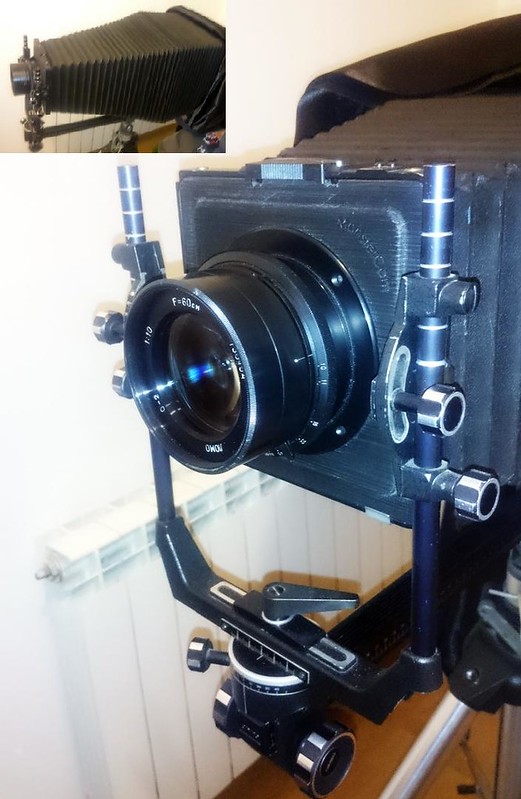

I printed this, but i'm having trouble with it...

I didn't design it, i just downloaded the file.

Description says i don't need to screw the lens in (it wont screw in very much anyway), but the lens wont stay put very well.

Gaffers tape might work, but I'm hoping someone else has figured this board out. The lens actually fell out while I was focusing it. Thankfully it didn't hurt the lens.

Here's the link.

https://www.thingiverse.com/thing:1569931

Thanks.

-A.

Reply With Quote

Reply With Quote

Bookmarks