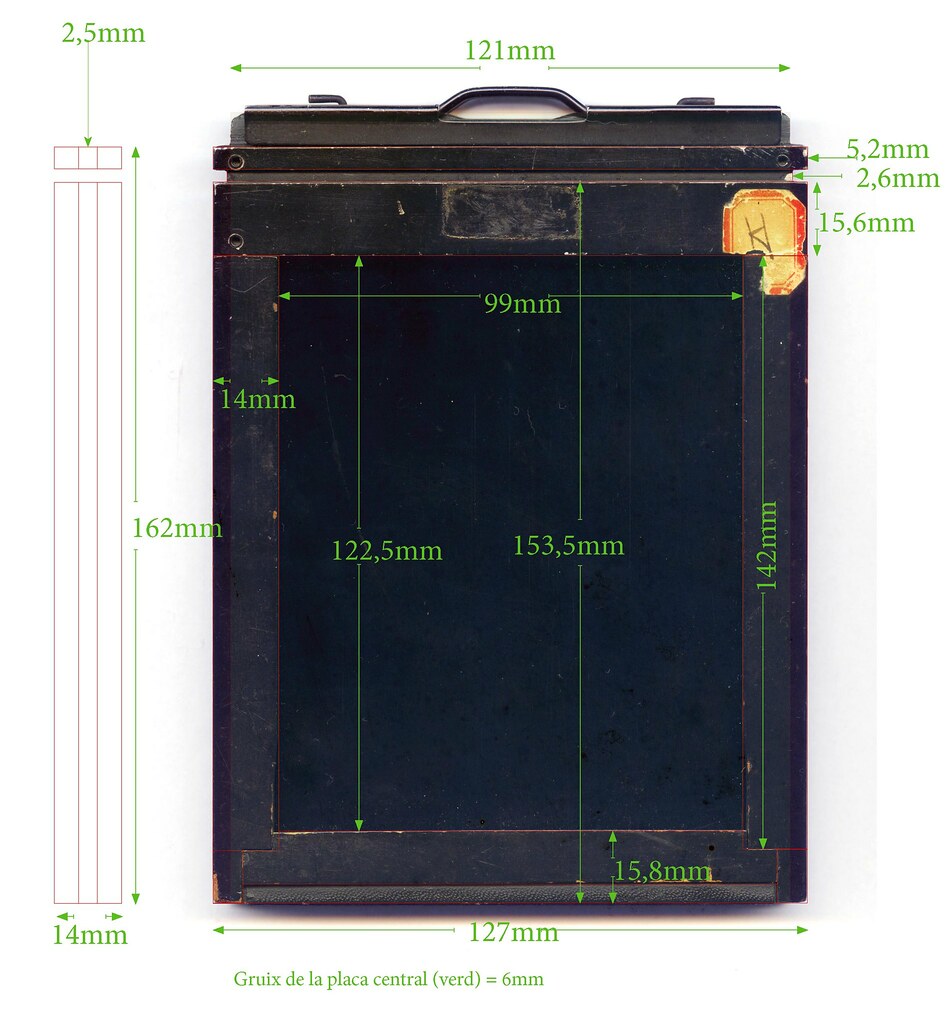

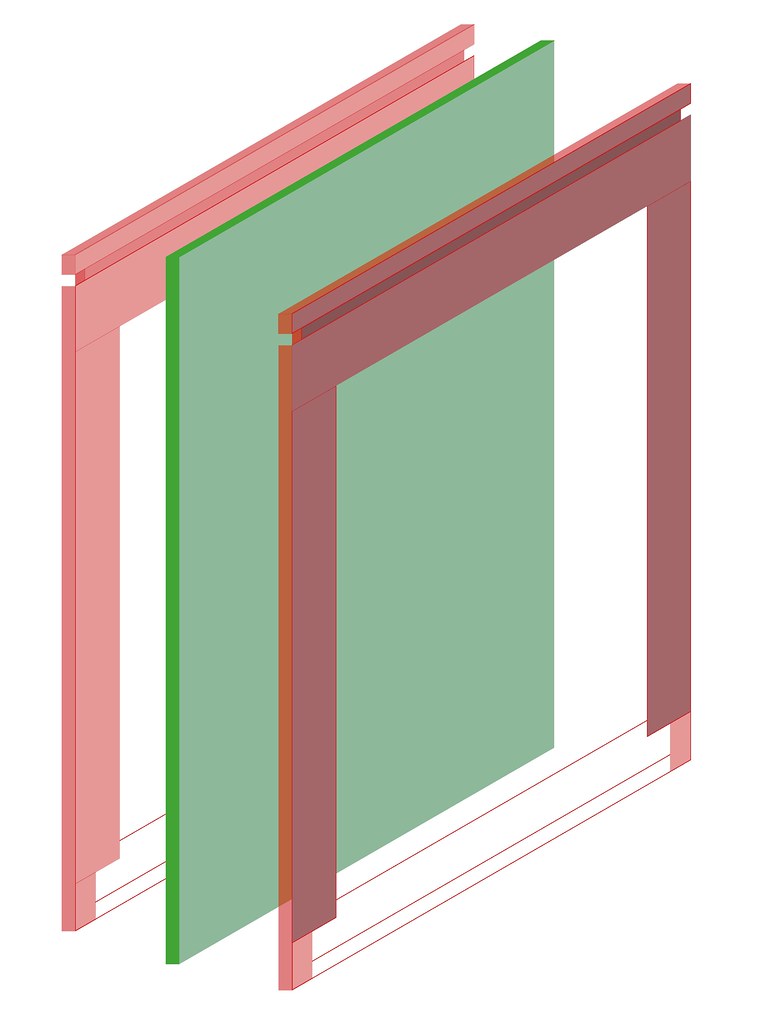

It has been several months that I have unsuccessfully tried to find slotted 4x5 Graflex film holders for the RB. Until it hit me I could probably copy one in a simple 3D design software. After all it doesn't seem there are very many parts.

The printing could go two ways. One could be making it in wood with an X-carve type of machine. The other would be using a 3D printer for which the more appropriate material should be used (I am thinking light safe).

Any ideas to which would work best? I would have to dig into figuring out the 3D software first.

As for the patent, once designed, could the template be shared for free without incurring in illegalities?

Good day!

Reply With Quote

Reply With Quote

Bookmarks